A R65.00 DC Power Supply Project for your Amateur Radio Equipment. Can this really be true? Read on and find out.

A year or so ago I ran into three old Dell PowerEdge Servers at an auction for R50 each. Nobody wanted them and I took them home. All three were in a working condition but were fairly old technology. I stored them in my container for a "rainy day". Well the rainy day arrived in April 2025 when I ran into a short article how to convert a server power supply into a low noise 12v DC Power Supply. Server power supplies are noisy and when the fans run at full speed it sounds like a turbo jet. Very very noisy indeed!

I intended to scrap two of the servers and keeping the smaller one for another "rainy day". After stripping of the servers I was left with many usable parts. I looked at the 4 x power supplies and realized that the one server's supplies does not have fans embedded in the power supply casing. However these two units were fed with air that circulated inside the server. These two looked like good candidates to modify into a low noise 12v DC Power Supply for Amateur Radio Equipment.

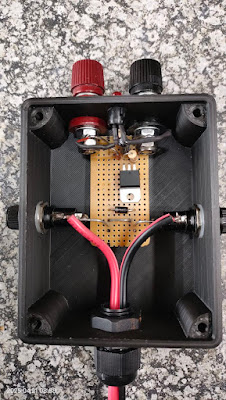

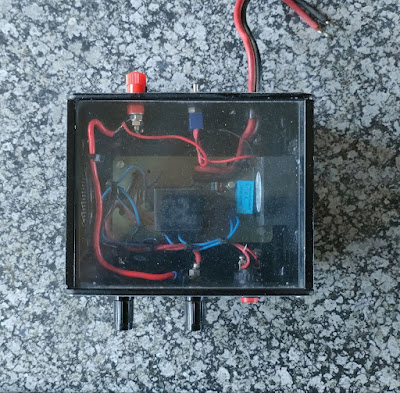

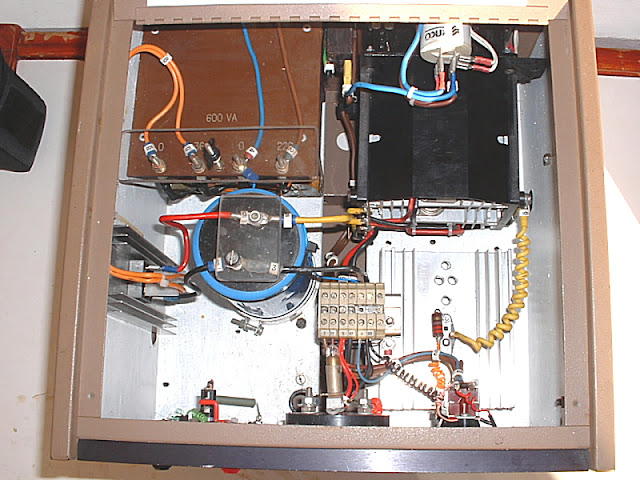

Here are some images of what the Server Power Supply looked like before any modifications. (Click on images for larger view.)

Herewith the specifications of the Dell Model D670P-S0:

Dell D670P-S0 SERVER

POWER SUPPLY

The Dell D670P-S0 is

a 670W power supply unit (PSU) with a 100-240V input, designed for

Dell PowerEdge 1950 servers, and features a 54.4A +12V output and a

5.25A +3.3V standby.

Here's a breakdown

of the Dell D670P-S0 power supply specifications:

WARNING: Please note that all server power supplies does not have the same jumper pin and power outputs. Ensure that you have all the information of the server power supply you want to modify. If not sure then do not go ahead with the modifications. Take care when working with any power supply as high voltages are present that are lethal and will kill you if you make mistakes or by accident. You have been warned!!

TAKE NOTE: For use as a power supply for Amateur Radio it may be best that the case be left connected to -12v. This may help to reduce RF noise from the switching power supply but experimentation will have to be done as to the best way to eliminate the RF. Interference will not be an issue on VHF radios but on HF radios the lower bands might be affected and is so RF filtering will be required.

Before I continue to explain how I went about to modify the Dell D670P-S0 Server Power Supply it is necessary to make mention of the fact that this project is not my idea or invention. I visited several Internet sites to gather information to undertake this project. There are an abundance of information on the Internet in this regard.

If you plug in the 220v AC plug the unmodified server power supply will not produce any 12 v output. We need to install jumper connections to enable 12 v DC output. Lets look at the pin header that will host the jumper connections.

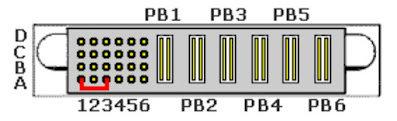

Image: Pin Header (Click on image for large view.)

STEP 1: Enable other Futures

For the Dell D670P-S0 power supply we need to jump pin A1 (plugged in) to A3 (ground) This jumper does not seem to alter power supply state in any way, other than to enable other features to work. There is no reason not to make this connection permanent if the supply is no longer being used in a Dell chassis.

STEP 2: Enable Main Power Output

Jumper from B6 (12V power enable) to B3 (ground). This should enable the main power outputs. We will be adding an OFF / ON Toggle Switch between these two pins.

STEP 3: Pin Diagram - Other Features

I use female DuPont cable sets for connecting the pins. They fit tightly and prevent any short circuiting to other pins. I added the off/on switch at a later stage as I wanted to see if the server power supply would startup correctly.

Now that we have all the pins connected it is time to add 220v AC to the input and measure the output voltage at the PB connectors. After switching on the 220v AC Input and a few seconds later the 12V DC Output came to life.

Take note that this power supply has no fan, so do not let it run for long periods until you installed a fan. The supply can get hot quickly and we do not want to damage the supply before all the modifications have been completed.

The next awkward modification is to modify the - Neg and + Pos connecting pins. I tried to solder thick copper wire to the PB pins but solder would not take on these pins. Now either the pins were very dirty or my soldering iron was on the cold side. Instead of trying to clean the pins or stuff up the pins I decided to use electrical female spade connectors that fits nicely over the PB pins. I soldered thick copper wire to the spade connectors and plugged the negative and positive "connectors" into the server power supply. Joining the outputs together like I did will provide 54 Amps of current. You can also make three output connections giving you about 18 Amps individually.

Once this modification is complete you may solder the output wires (Black + Red) to the thick copper wire and you are ready to use the power supply. If you tied the outputs like in the image above use 4.8 mm wire @ 54 Amps . If not tied use 2.6 mm wire @ 3 x 18 Amps.

I wanted something that looked better and that protects all the connections, furthermore the fan needed to blow all the air through the supply. Leaving it open will not provide sufficient air flow. I found a 3D printer cover for the server power supply. After printing the cover on my 3D printer I was not happy with the strength, thickness and cover distance of the cover.

I decided to roll my own cover with Free-CAD and printed the cover on my 3D printer. I added the On/Off switch between B3 and B6. As mentioned before this server power supply has no fan to keep it cool. No problem! I took one of the server fans but from experience I know that when these fans run at full speed they make a heck of a noise. To curb the noise but still have a decent amount of airflow in the server power supply, I had to either control the the fan using a thermal switch or install a switch between B2 and B3. Open is Hi, Closed is low.

I however choose the easy way out by adding a resistor in the positive line of the fan. I used a 47 Ohm 5 watt resistor. You can play around with the value of the resistor but ensure that you use a 5 watt component as this resistor gets fairly hot. To keep this resistor as cold as possible I mounted it on top op the pin connectors where the fan can furthermore keep the resistor and the power supply unit cold. This is an easy solution and worked like a charm.

After all the connections was made I used the hot-glue gun to "isolate" them. Furthermore the hot-glue prohibit the wires from breaking off or become loose. Next I installed the fan, switch and black compression glands. It took some effort to fit everything through the open end but I managed to complete the task. Next time I will re-design the 3D cover to make it easy to fit all the parts and components.

Once again time to test the modified server power supply. The end result is a working 12.37v DC, 54.5 Amp power supply. Most of the server power supplies do have different protection circuitry, however I chose to add my own Crowbar Unit to this supply for "extra" protection. More on this project, click HERE.

Finally: Total cost of this project amount to R65.00 (excluding the add on Crowbar Unit.) I will test this supply further and will do a follow up article on my findings. So far I think all the effort was worth it and I am now the proud owner of a high current DC power supply.

Images: (Click on images for larger view.)

.jpg)